Jeans or Cotton Pants Manufacturing Process

We are presently engaged in the business of manufacturing of readymade garments for men and kids. We purchase Fabrics from the wholesaler of denim as well as cotton. This material is being processed by many job workers to make the final products.

Denim is selected from large batches based on quality and color specifications for production.

Patterns for different garment parts are laid out on paper, optimizing fabric usage and minimizing waste.

Fabric layers are spread evenly on a cutting table to ensure consistent grain and tension.

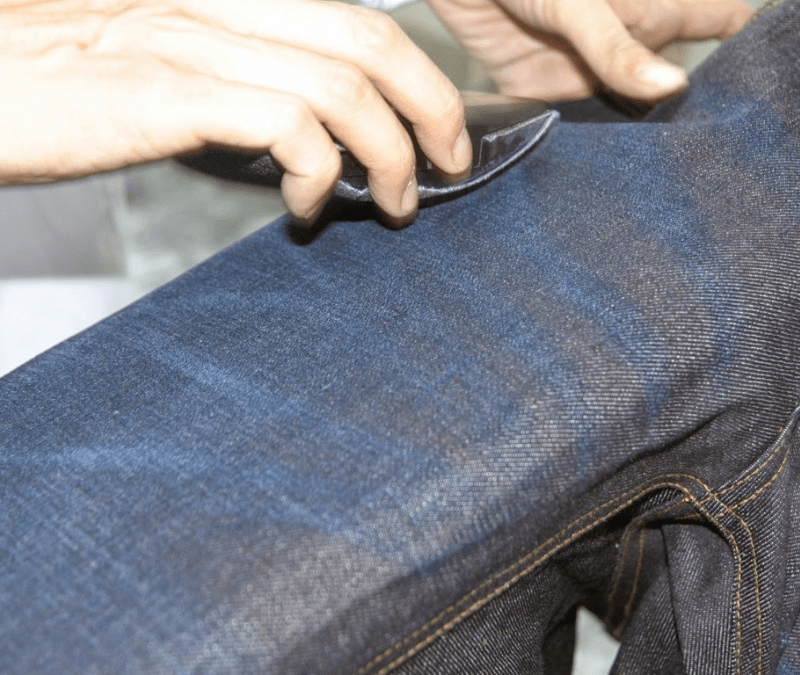

Patterns are placed on the fabric and cut using automated cutting machines for precision.

Cut fabric pieces are sewn together to form the garment, including all seams and embellishments.

Garments undergo various washing techniques like enzyme wash or stone washing to achieve desired softness and texture.

Additional details such as buttons and zippers are added, and garments are pressed to enhance appearance.

Each garment is inspected for quality and adherence to design specifications.

Garments are folded, tagged, and packaged in protective materials ready for shipment.

Packaged garments are stocked in inventory, ready for distribution and sale.

- Cutting and Stitching (Average Time: 1-1.5 Months)

- Washing and creation (Average Time: 0.5-1 Month)

- Finishing and Packing (Average Time: 0.5-1 Month)

The final product comes from job workers which is ready to sale takes minimum 3-4 months depending upon various factors. Hence we have to plan accordingly and maintain stock accordingly. Therefore stock in hand has to be available for more than one third of the total sales forecasted. Thus most of the times output tax liability is being setoff against the input credit. Further we want to state that we have paid more than one lakh income tax since inception of the firm. We are attaching copy of acknowledgment for your ready reference.